Hi I am Cory Flemings from abco automation. Do you have a single technology distribution center? Do you basically pick all your SKUs the same way? If that’s the case you may be missing some huge opportunities for efficiency and I would like to show you why.

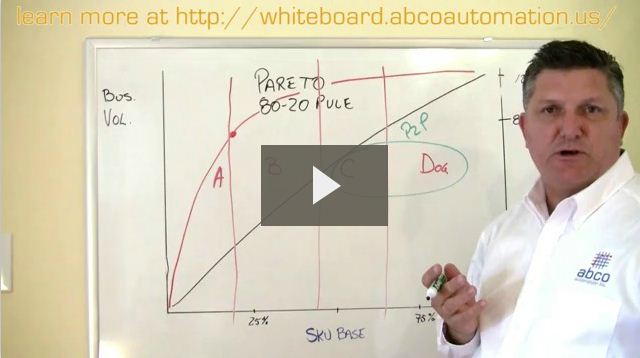

In the 19th century there was an Italian guy named Vilfredo Pareto. And he is responsible for the Pareto Curve or the Pareto Principle. We know it today as the 80/20 rule, as we have applied it to business.

The 80/20 rule basically states that 20% of your SKU base does 80% of your volume. That’s right 80% of your volume is done by 20% of your SKU’s. And conversely 80% of your SKU’s do only 20% of your volume.

So what does that have to do with your distribution center design? Well if you’re picking all of your SKU’s the same way then you are forgetting this principle. You are assuming that every SKU that you add moves the same way as the last one you added. So you have a linear function on this curve. Well, kind of linear.

So as I add from 25 to 50% I am adding from 25 to 50% of my business volume. Whether I measure my business volume in lines, in pieces, in red ramzonics, however you want to metric your business volume it really doesn’t matter. You are assuming in a one technology system that everything gets picked the same. But Pareto says this, Pareto says 20% of my SKU base, does 80% of my business volume. And it looks like this.

You’ll notice that we wear really groovy shirts at abco automation that have the Pareto Curve built right into them. And that’s because we think you can really leverage the difference between this linear relationship in this Pareto curve. This Pareto curve, again, suggest that 20% of your products do 80% of your volume.

Why then would I take those SKU’s the same way that I take these SKU’s down near the end which I will say are my “D” SKUs, if I put letters on them. Or my ‘Dog” SKUs. These SKUs down at the end they might only do 4% of your business volume and with the “C’s” together somewhere between 10 to 15% of my whole business volume. Yet they are going to represent 50% of your SKU base.

And if you are a distribution center operations person you’re slapping your forehead saying “Why do we even bother carrying these things will well it doesn’t matter what products you carry, you will always have this Pareto effect.

So why’d you pick them all the same way?

These products that are down here at the end can have some technology applied to them these two things here in products that I call products-to-person technologies. They might be carousel systems or shuttles but they are technologies or vehicles that bring products to the picker. Instead of the picker going out and passing 80% of the SKUs in the warehouse to find the one that they need. These products or technologies bring them to the selector instead. (A distribution center design can realize) a huge benefit in the efficiency of picking these orders here.

Over here on the other end you have 20% of your products that are doing 80% of your volume. Why would you move these products around? These products need to be stationary or stay in one area and they can be picked. Often times the problem you are dealing with here is how is do you replenish them fast enough.

In both cases automation can be used to help select these and select these, differently. Do you have, as I asked earlier, a single technology warehouse? Well then you can see now there are some huge differences in efficiency that we can apply to help make your distribution center design more efficient.

Give us a call at abco automation 803-517-7537 we can help do the analysis and carve your Pareto curve up with the proper technologies. Because we do the math.